A third-generation semiconductor made from gallium nitride, with technical features that enable it to achieve three times the charging power of older silicon chips at half the size and weight.

Cell phone charger is only one of the application scenarios of gallium nitride chip. According to public information, there are commercial applications in personal computers, data centers and other fields, and is expanding to solar energy, electric vehicles and other fields.

Looking back at the history of the semiconductor industry, changes in new technologies and new application scenarios have always profoundly affected the industry landscape. When silicon changed from bipolar to MOSFET (bipolar to MOSFET), it gave rise to many new power supply design companies.

But it's not easy to drive new technologies from concept to business. Compared with silicon devices, the high cost of GaN devices is also a problem that needs to be solved. The cost of GaN devices mainly comes from the development and production of chip epitaxy, foundry (fab process) and packaging. In order to further realize the high-frequency characteristics of Gallium Nitride, a proprietary PDK kit high-frequency package is used, and a fabless model is adopted for foundry. In the future, we will further improve the process yield and reduce the die (bare crystal or die, which is an integral part of a chip. The area of die (die is a part of the chip that is cut from a wafer and packaged to become a chip) will be further improved in the future to reduce costs.

As the gallium nitride application ecology is still in the development stage, the difficulty of using gallium nitride devices for product design is also relatively high, which is also reflected from the side, gallium nitride-related industry ecology is not yet perfect. With gallium nitride supporting high-frequency controller, high-frequency magnetic core and other equipment still exists in the absence of the situation. Magnetic devices, for example, gallium nitride devices have been able to achieve more than 10M switching frequency, but the highest value of the magnetic device frequency is only 400k to 500k.

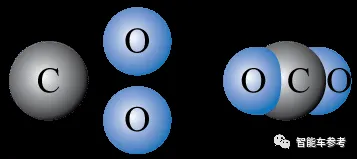

On the other hand, compared with silicon chips, gallium nitride chips emit relatively little carbon dioxide. According to statistics, by 2050, if more than 50% of silicon devices can be converted to gallium nitride devices, then the entire global carbon emissions can be reduced by 10%.

Reduce the cost of gallium nitride devices, improve the industry ecosystem of gallium nitride, expand new application scenarios will be the problem that must be solved. But these are by no means overnight, the popularity of gallium nitride chips also need time.

(Article source: Noodle News)

[Zhongshun Xinneng Marketing Department October 11, 2021 Responsibility: Xiao Zheng]

* Reproduced for the purpose of transmitting more information, and does not mean that we endorse its views and are responsible for its authenticity.