Successive news of major breakthroughs in solid-state batteries released in the academic community seem to signal that this field, which is generally viewed favorably by the industry, is on the verge of a qualitative breakthrough.

The latest research results published in the journal Science by a research team from Tokyo Institute of Technology show that an all-solid-state battery with high-capacity and high-current characteristics has been successfully realized, thus making these two properties a new benchmark for solid-state batteries worldwide. Almost at the same time, the internationally renowned academic journal "Nature Communications", also published the latest research results of the University of Science and Technology of China Professor Ma gallop - a comprehensive performance and the current state-of-the-art sulfide, chloride solid-state electrolyte similar to the new solid-state electrolyte, but the cost is less than 4% of the former, suitable for industrialized Application.

Do technological breakthroughs mean increased industry maturity? How far is the road to commercialization of solid-state batteries?

Cost, or cost

When the liquid electrolyte as the main body of the power battery domestic June single-month loading has been close to 33GWh, behind it is a mature process system; however, in the face of semi-solid batteries, a new thing, the previous inherent process system will be partially reconstructed. "For example, the liquid battery coating machine can complete hundreds of meters per minute, but solid-state, semi-solid battery production can only match its (coating machine) 1/30," the industry source cited as an example, which greatly reduces production efficiency and increases costs. "At the same time, because of the new process, the product yield also affects the cost to a certain extent."

Systematic change

This is already the case for semi-solid-state batteries, which have some similarity to liquid batteries, and cost control for truly all-solid-state batteries is even more complex.

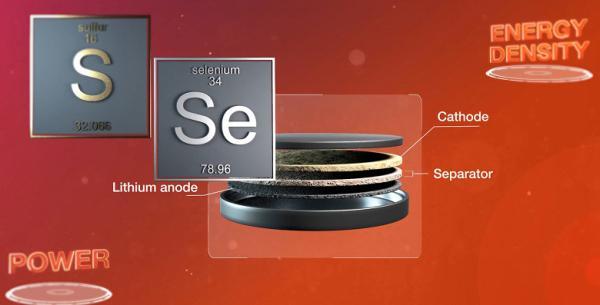

The research results from the University of Science and Technology of China (USTC), published in Nature Communications, show that instead of focusing on any of oxides, sulfides, or chlorides, Prof. Ma Zang's research turned to oxychloride to design and synthesize lithium zirconium oxychloride, a new type of solid-state electrolyte. This material has a strong cost advantage. If hydrated lithium hydroxide, lithium chloride, and zirconium chloride are synthesized, its raw material cost is only $11.6 per kilogram; and if hydrated zirconium oxychloride, lithium chloride, and zirconium chloride are synthesized, the cost of lithium zirconium oxychloride can be further lowered to about $7 per kilogram, which is much lower than that of the most cost-advantageous solid-state electrolyte currently available, lithium zirconium chloride ($10.78 per kilogram) and is less than that of sulfide and 4% for the rare earth-based, indium-based chloride solid state electrolyte.

The constraints to commercialization of all-solid-state batteries are systematically analyzed from three aspects - first, for all-solid-state batteries to go from laboratory technology to mass production and delivery, enterprises must first master the R&D and production capacity of all-solid-state electrolyte materials as well as key technologies such as the introduction process; second, because the "solid-solid contact" between the all-solid-state electrolyte and positive and negative electrodes is relatively poor, the interface impedance problem is also a necessary condition for the production of all-solid-state batteries; third, the most critical is the selected technology route and material system. Second, because the "solid-solid contact" between the all-solid electrolyte and the positive and negative electrodes is poor, and the interfacial impedance is high, solving the interfacial impedance problem is also a necessary condition for the production of all-solid-state batteries; third, the most critical thing is whether the selected technology route and material system can be scaled up for mass production, and to find a balance between the performance of the product and the control of the production cost are important influencing factors to determine the successful commercialization of the battery manufacturers. important influencing factors for commercialization.

Ten-year critical period

Although the commercialization of all-solid-state batteries face many difficulties, but the industry is still optimistic about this new thing with higher energy density, higher safety, longer cycle life and better low-temperature performance and other performance advantages.

According to incomplete statistics, since 2022, there have been 8 domestic enterprises related to the field of solid state battery manufacturing have obtained nearly 40 rounds of financing. Among them, in 2022, the financing process in the field of solid state batteries is quite fast, and 8 enterprises have completed a total of 12 rounds of financing.

Toyota, the world's first to lay out solid-state batteries, announced in early July that it had made a major breakthrough in solid-state battery technology, enabling it to halve the weight, size and cost of batteries, and plans to launch electric vehicles equipped with advanced solid-state batteries by 2025.

Seems to be as Toyota's "assist", in the field of scientific research, Japan's Tokyo Institute of Technology and other institutions recently published in the journal "Science" paper that it has developed a highly conductive solid-state electrolyte "lithium super-ionic conductor", and successfully used this new type of Electrolyte to make all-solid-state lithium battery characteristics have been significantly improved.

Globally, solid-state batteries have been "war". According to public information, the United States plans to achieve large-scale mass production of solid-state batteries and lithium metal batteries by 2030; Japan plans to achieve mass production of all-solid-state batteries by 2030; South Korea will invest 306.6 billion won in 2023-2028 to achieve the early realization of solid-state batteries, lithium metal batteries, and other commercial applications; and the European Union has approved the participation in the battery project to provide 3.2 billion euros of assistance to the seven member states to support battery technology research and program innovation.

There is no doubt that the decade to 2030 will be a critical period for solid-state battery wrestling.